| Company: | Qingdao Wanan Electronic Technology Co., |

| Location: | China - Shandong,275 Chongqing North Road, Chengyang District, Qingdao City |

| Price: | 2000/set |

| Contact: | qianhuihui(Salesperson) |

| Contact Me: |

Mobile:+86-18561906130 |

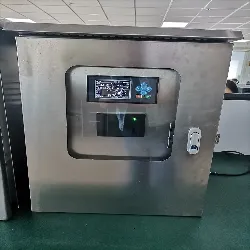

IC card steam prepayment system, steam card recharge system

IC card prepaid application scope:

Applicable fields: development zone heating, municipal heating, power plants, steel mills, municipal water supply, development zone water supply, sewage treatment, gas sales, etc

Applicable units: thermal companies, heating companies, power plants, steel plants, water plants, sewage treatment plants, gas companies, development zone management committees, environmental protection departments, water conservancy departments, etc

Applicable media: steam (saturated steam, superheated steam), natural gas, hot water, tap water, domestic and industrial wastewater, etc

Applicable pipe diameter: DN4-DN1000

Prepaid steam flow meter is composed of steam flow meter with remote communication interface, electric valve, GPRS/CDMA wireless transmission DTU module, public wireless network, terminal computer, and centralized meter reading management system software.

Technical characteristics of prepaid steam flow meters

1. Wireless remote transmission function and data upload

The anti-theft prepaid control box is equipped with a built-in GPRS/CDMA wireless transmission DTU module, which can easily upload user's instantaneous flow, cumulative flow, temperature, pressure, balance, valve opening, box door opening and closing status and other information to the computer in the monitoring room. At the same time, the upper computer configuration software can be combined to analyze anomalies in temperature, pressure, and flow to determine instrument faults, and to achieve remote meter reading function.

2. Open box door alarm recording function

To avoid customers colluding with maintenance and meter reading personnel to open and modify instrument coefficients, the control box is not only equipped with double locking facilities, but also has an open box alarm function. Once the box door is opened, the system automatically uploads the status of the box door.

3. Historical curve storage function

The flow integrator has a full Chinese screen and can store historical records of temperature, pressure, and flow for 365 days. In case of unexpected disputes, it can be easily queried.

4. Power outage time recording function

To prevent users from stealing through power outage, the accumulator is equipped with a power outage recording function, which can record the time of nearly 20 power outages for easy query.

5. Backup power function

The system is equipped with a backup power supply that can maintain a continuous power supply time of more than 72 hours. Notify the upper system of an alarm in a timely manner when using a backup power supply.

6. Realize paying fees first, then using steam. If the balance is insufficient, an alarm will be triggered to charge. When the balance is zero, the valve will be closed by oneself

7. The IC card prepayment control system implements one meter, one card, and has strict multi-layer confidentiality functions, which cannot be copied. The card free prepaid control system directly distributes the recharge amount from the upper computer, and users can better protect the controller from being cracked without touching it.

8. Prepaid function

Place the recharged IC card close to the IC card reading and writing area, and the prepaid controller will automatically read out the amount on the IC card and store it in the memory device of the controller, while clearing the IC card to zero. Alternatively, the recharge amount can be remotely sent to a specific storage device within the controller, where the CPU performs a series of processes such as calculating and comparing two sets of data, making logical judgments, etc. When the value charged (i.e. the tonnage of steam purchased this time) decreases to insufficient margin, the buzzer in the instrument will sound an alarm (or send a text message to inform). When the margin drops to zero, the control instrument will send a command signal to disconnect the electric valve and close the valve.

9. Communication function: This controller has an RS485 or RS232 communication interface that can be connected to the GPRS module. Without changing the original remote transmission function, all parameters on the integrator (temperature, pressure, cumulative flow rate, frequency, differential pressure, power outage time, remaining amount of IC card, valve status, power supply status light parameters) can be remotely transmitted to the central monitoring room.

Technical characteristics of steam remote measurement and control management information system

The steam remote measurement and control management information system is developed to meet the needs of informationization construction in heating enterprises and achieve the goal of informationization management in heating process measurement and control. This system realizes real-time measurement and control of various steam parameters in the heating system, user recharge to automatic statistical reports, abnormal alarms, recharge reminders, steam leakage diagnosis, and other dynamic management throughout the entire process.

Advantages:

1. Steam parameter measurement: Users can adjust various parameters according to different situations.

2. The remote control method of the valve is achieved through the upper computer in the central control room to remotely open and close the valve.

3. Remote Recharge: Users only need to transfer the car payment to their thermal power plant account. After receiving the car payment, the thermal power plant's management personnel will recharge the user through wireless communication in the monitoring center and send a text message to remind the user that the recharge is successful.

4. Abnormal operation alarm: sound and light alarm, concurrent SMS notification alarm.

5. Steam parameter change curve: visually observe the usage of steam.

6. Pipeline fault diagnosis: To ensure balanced pressure in the pipeline network and meet the requirements of most users.

7. Report statistics: According to requirements, reports on daily, monthly, and annual usage can be compiled, printed, and queried.

8. Resource sharing: Users can log in to the system on any computer within the Internet to view real-time status information and achieve resource sharing.

9. Permission management: Users can assign management permissions based on their level to meet different management needs.

10. Remote maintenance: Authorized by the user, it can assist in system maintenance and upgrades to ensure stable and reliable operation of the system.

11. On site data monitoring: The prepaid recharge system uploads user's steam usage data information through wireless communication networks. The upper computer analyzes and organizes the received data, automatically providing users with desired curve charts and reports, providing real-time on-site information for management personnel.

12. Automatic billing: The remaining amount (remaining tonnage) in the prepaid controller will be charged in real-time based on the on-site steam consumption situation.

13. Time of use billing: Divide a 24-hour day into two time periods, with different unit prices charged for each time period.

14. Remote modification of unit price: The operator in the main control room adjusts the user's steam consumption unit price through wireless communication network.

15. Rich alarm signal feedback: power outage alarm and unboxing alarm, etc.

16. When the balance in the controller is insufficient, the system promptly sends a text message to the user to remind them to recharge in a timely manner.

Qingdao Wanan Electronic Technology Co., Ltd.'s main products include vortex flow meters, electromagnetic flow meters, turbine flow meters, display instruments, heat meters, differential pressure instruments, analytical instruments, water quality monitoring equipment, pressure instruments, etc., as well as undertaking electrical automation projects. Welcome to inquire by phone.

Disclaimer:All information is provided by registered users. You may assess risks based on corresponding qualifications.

IC card steam prepayment system, steam card recharge system

IC card steam prepayment system, steam card recharge system

Steam vortex flowmeter, boiler steam meter

Steam vortex flowmeter, boiler steam meter

![CA-12P1N128007S - Cable connector]() CA-12P1N128007S - Cable connectorCA-12P1N128007S - Cable connector 1619521 M23 , Cable connector , series : CA , straight , shielded : yes , SPEEDCON , No. of pos. : 12 , Direction of" "

CA-12P1N128007S - Cable connectorCA-12P1N128007S - Cable connector 1619521 M23 , Cable connector , series : CA , straight , shielded : yes , SPEEDCON , No. of pos. : 12 , Direction of" "![BTP 2043W - Touch panel]() BTP 2043W - Touch panelBTP 2043W - Touch panel 1050387 Touch panel with 10.92 cm / 4.3 " TFT display ( analog resistive ) , 480 x 272 pixel( s ) ( WQVGA ) , 16.7 million colors ," "

BTP 2043W - Touch panelBTP 2043W - Touch panel 1050387 Touch panel with 10.92 cm / 4.3 " TFT display ( analog resistive ) , 480 x 272 pixel( s ) ( WQVGA ) , 16.7 million colors ," "![ILC 151 ETH - Controller]() ILC 151 ETH - ControllerILC 151 ETH - Controller 2700974 The Inline controller offers the option of communicating via PROFINET and Modbus/TCP." "

ILC 151 ETH - ControllerILC 151 ETH - Controller 2700974 The Inline controller offers the option of communicating via PROFINET and Modbus/TCP." "![UNO-PS 2AC 24DC 90W C2LPS - Power supply unit]() UNO-PS 2AC 24DC 90W C2LPS - Power supply unitUNO-PS/2AC/24DC/90W/C2LPS - Power supply unit 2904371 Primary-switched UNO POWER power supply for DIN rail mounting , input : 2-phase , output : 24 V DC/90" "

UNO-PS 2AC 24DC 90W C2LPS - Power supply unitUNO-PS/2AC/24DC/90W/C2LPS - Power supply unit 2904371 Primary-switched UNO POWER power supply for DIN rail mounting , input : 2-phase , output : 24 V DC/90" "